leak test in autoclave|steam penetration test autoclave : broker While it’s not a substitute for sterility assurance testing, the Bowie-Dick test cycle demonstrates proper air removal from the chamber of a pre-vacuum autoclave. Pockets of cool air can form inside the chamber of a pre-vacuum autoclave, acting as . See more Las bolsas de esterilización en autoclave son dispositivos diseñados para mantener instrumentos y equipo médico libres de microorganismos patógenos, asegurando que estén en condiciones óptimas .

{plog:ftitle_list}

In this manual, pictorial indications are used to ensure safe operation of the autoclave. Safety indications are classified into "Warnings" and "Cautions" depending on the level of potential .

While it’s not a substitute for sterility assurance testing, the Bowie-Dick test cycle demonstrates proper air removal from the chamber of a pre-vacuum autoclave. Pockets of cool air can form inside the chamber of a pre-vacuum autoclave, acting as . See moreWhat is a Bowie-Dick test? A Bowie-Dick test is a standard operational test that laboratories can use to determine proper air removal from their . See more

A vacuum leak test is used to determine the air-tight integrity of a pre-vacuum autoclave’s chamber and plumbing system. This test . See moreWhat is a Steam Sterilizer (Autoclave) Leak Test? A vacuum leak test is used to verify the .Chamber vacuum leak rate test . responsibility of the autoclave user • For tightness testing purposes, the chamber is pressurized by compressed air to a pressureof 2 to 3 bar abs • As compressed air injected into the chamber will increase in temperature, a

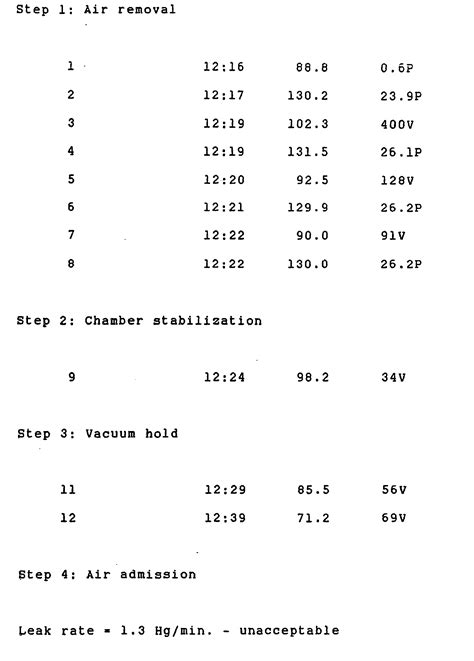

During the test, the autoclave is subjected to a vacuum cycle, and the amount of vacuum lost over a specific period is measured. A typical cycle includes three vacuum pulses, followed by a 15-minute hold time in a deep vacuum. At the end of the test, the leak rate is measured in units such as kPa/min, mbar/min, or mmHg/min. Autoclave Vacuum Leak Testing. As the name implies, vacuum leak testing checks the air-tight integrity of the autoclave chamber. On most autoclave models, this will be a specific factory-programmed cycle that will put your autoclave through its paces and log how much “vacuum depth” is lost under specific conditions over a given time period. .

Detecting autoclave air leaks with process challenge devices: A comparison study Paul N. Holt — Senior Product Development Engineer . Bowie-Dick Test Results – Control Cycles (No Air Leak) Test Type Lot Number Cycle 1 Result Cycle 2 Result 3M Comply Test Pack 1233LF 2015-10AD PASS PASS Steris DART Test M13113 PASS PASS PCD Test Results .

This is not possible, which supports why air-removal tests are still very relevant to today’s modern sterilizers for autoclave testing. The Vacuum Leak Test programmed on your autoclave only measures the integrity of the sealed pressure vessel and associated piping to ensure air is not admitted to the sterilizer during the vacuum drawdowns. An autoclave is a machine that uses steam under pressure to kill harmful bacteria, viruses, fungi, and spores on items that are placed inside a pressure vessel. The items are heated to an appropriate sterilization temperature for a given amount of time.The Vacuum Leak Test is used to determine the air-tight integrity of a pre-vacuum autoclave’s chamber. Vacuum leak .

vacuum leak test acceptance criteria

alemtuzumab elisa kit

Related: Autoclave Basic Components, Leak Test used in Autoclave, Autoclave Types, biological indicator for autoclave. Important Parameters of an Autoclave. The following factors affect how an autoclave operates and needs to be maintained: Autoclave Temperature and PressureAn autoclave control unit 4 tests operation of the autoclave by turning on a pump 10 to evacuate the pressure vessel 1 and then monitors rise in pressure within the vessel to detect any leaks. If the leakage rate is too high the control unit 4 may disable the steriliser, preventing further sterilisation cycles being started until the leak is corrected.

Chamber vacuum leak test If P2 –P1 20 mbar, probably the test has been performed while the chamber is moist If P3 – P2 13 mbar, the leaks that are evidently present and must be eliminated Today, most autoclaves have an automatic program for a routine tightness test, which is "analyzed" by the pressure measurement systems of the autoclave . Vacuum leak test procedure is explained this video by using STERICOX Class B Sterilizer Classic Model. It is 23 liters Class B Autoclave, which is used by De. LEAKAGE TEST: An air leakage test for autoclave chambers is done to find out any leakage from the chamber. Air leakage test is used to establish that the quantity of air leakage into the sterilizer chamber during the period of vacuum does not exceed the level. air leakages will obstruct the penetration of steam into the sterilizer load and the .

Running a Bowie-Dick Test requires placing a small, disposable test pack into the autoclave and running a four-minute sterilization cycle, typically a Bowie-Dick Cycle. . Air Leak: Run a Vacuum Leak Test to further determine if an air leak exists or not. Unwanted Condensation: Check the steam traps on the autoclave. Check steam quality and .Procedure for Vacuum Leak Test . The Vacuum Leak Test is used to evaluate the air-tightness of the chamber and pipework of a pre-vacuum autoclave.; In this test, the piping and parts of the autoclave are subjected to vacuum conditions, and the amount of vacuum depth lost over a predetermined time is recorded.

alere lyme test kit elisa

Vacuum Leak Test is a test for autoclave requested by the UNI EN ISO 13060 standard. It consists in checking if a fixed increase of pressure is present between two specific periods of the process. The purpose is to check that there is no leakage in .As autoclaves Classe B Pré-Vácuo de marca Woson trazem entre seus programas os testes Bowie-Dick, Helix e teste de vácuo, este último conhecido internacionalmente pela expressão leak-test ou leak-testing. A palavra inglesa leak em português significa vazamento. Logo, leak-test ou leak-testing são expressões que se traduzem por teste de .N o te s : AtypicalLeakTestcyclewilloperateasfollows: StageON E willbetheinitialpull-down. Onceatthepre-setvalue(A),thevacuumpumpwill STOP StageTWO isthefirsttimer .The different tests are follows for qualification of autoclave are: – Vacuum leak test Bowie-dick test Heat distribution study. Empty chamber; Loaded chamber; Heat penetration study VACCUM LEAK TEST: – This test is used to verify the leakage in sterilization chamber during vacuum hold time when the sterilizing chamber is empty.

Leak testing, a vital part of a leak test procedure in pharmaceuticals, is essentially the quality and safety gatekeeper in this industry. Consider the analogy of a fortress with a tiny, unnoticed crack in its wall. Over time, external elements could seep through this crack, compromising the fortress’s integrity. .heat penetration test were equipment passes all test and the equipment is suitable for sterilization purpose which meeting its predetermined specification and quality attributes. Keywords: Autoclave qualification, Sterilization, Vacuum leak test, Bowie-dick test, Heat distribution test, Heat penetration test. Introduction Definition of Autoclave

Performance Qualification Protocol for Steam Sterilizer (Autoclave) and Procedure for Vacuum Leak Test, Steam Quality Test, Bowie-Dick Test, Heat Distribution Test, Hest Penetration Test and F0 Calculation.1. A: SPD will run a daily Bowie-Dick Test immediately after running a leak test on all sterilizers in spd and OR. The George Isaac Surgery Center will perform these tests Sunday through Thursday. The Leak test will be run as an empty load. The sterilizer cycle will be set on (Leak Test.) The range of acceptable leakage is 0.0mm up to 0.9mm of .leak testing Venice, 22. March 2019 Presenter: Dr. Matthias Kahl, Head of R&D WILCO AG, CH. 2 Overview • Fundamentals of DP method –LFC, P, V (different types) –pressure curve / course –steps of the differential pressure test • Method selection • Equipment in process control

“The Bowie and Dick test was conceived as a test for . successful air removal for vacuum porous load sterilizers. A successful Bowie and Dick test indicates rapid and even . penetration of steam into the standard test pack or reduced test pack.” ISO 17665-1, Section 12.1.6 “If the sterilization process relies on the removal of air from theThe Leak test or Vacuum test is designed to examine air-tight integrity and the presence of leaks in an autoclave chamber and pipes. The chamber is brought to vacuum conditions of 7 kPa (after approximately 200 seconds in the above graph), and all valves and motors are closed for 5 minutes, enabling pressure stabilization.A vacuum leak test is performed on an autoclave to check for any leakage. This test is also called a chamber integrity test. This test is also called a chamber integrity test. The test exposes the autoclave ’s plumbing and components to vacuum conditions and measures how much vacuum depth is lost over a given period of time.All validated steam sterilization cycles provide efficacious autoclave sterilization when used according to manufacturer . The Bowie-Dick test is conducted daily to ensure that the vacuum system is adequately removing air from the chamber and should be used in conjunction with a weekly leak test to determine if there are leaks in the .

Sterilizers: Different Repairs, Different Testing Requirements Both documents describe the testing that should be performed after sterilizer malfunctions, relocation, and repair as “qualification testing.” Qualification testing guidance is explained in both documents under section 10.8, “Qualification tests.” This section details the pro-

sterilizer leak test parameters

aleutian disease elisa kit

Here is an item that you should use regularily in order to verify that .

leak test in autoclave|steam penetration test autoclave